Lithium industry

Application of Decowell EX series card I/O in lithium battery production line

Background of the lithium battery industry

Against the background of the rapid development of industries such as electric vehicles, electric light vehicles, power tools, consumer electronics

and new energy storage, the comprehensive advantages of lithium batteries are consistent with the increasing demand for large-capacity, high

power, service life, and environmental protection in downstream fields, and there is a broad market application prospect.

01 Lithium battery production line industry process

The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is

the basic structure of automotive power batteries.

The battery is like a container for storing electrical energy. The amount of capacity that can be stored is determined by the amount of active

the material covered by the positive and negative electrodes.

The design of positive and negative electrode plates needs to be tailored to different models. The gram capacity of positive and negative

electrode materials, the ratio of active materials, the thickness of the pole piece, the compaction density, etc. are also crucial to the capacity.

This application project of Decowell is applied to square battery cell assembly and Park assembly scheme and is mostly used in fully automatic

battery cell hot press, fully automatic battery cell pairing machine, fully automatic ultrasonic welding machine, fully automatic adapter welding

machine, fully automatic Mylar packaging machine, fully automatic battery cell shell machine, fully automatic top cover welding machine, fully

automatic sealing nail welding machine, fully automatic ammonia inspection machine, and other machines. The processes completed by these

machines are important processes in the lithium battery industry.

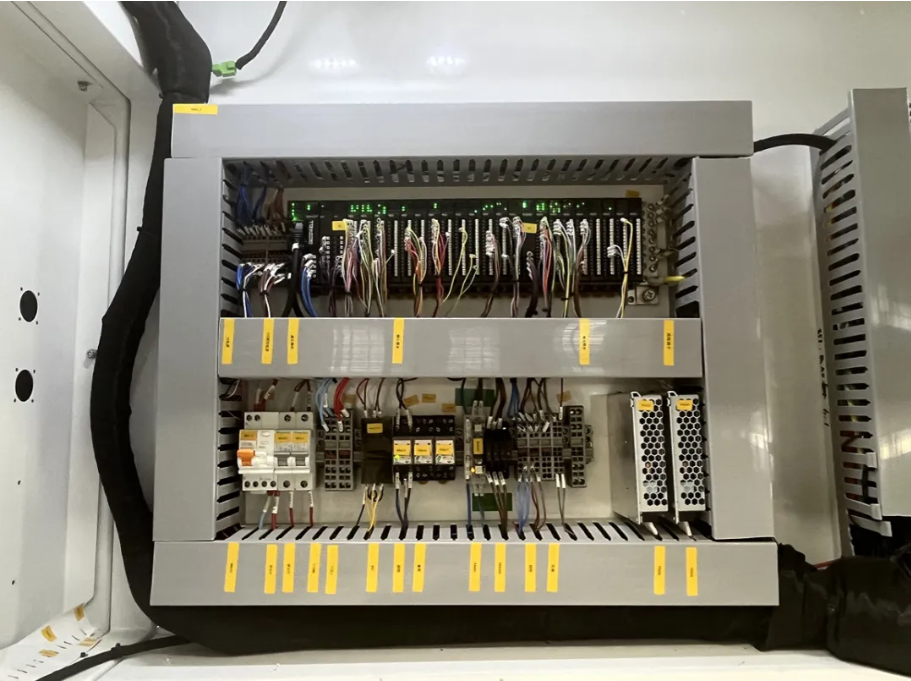

02 Module application

In this application project of Decowell, the PLC used by the main station uses the EC communication interface of the main body to communicate

with the Decowell remote IO module.

Among them, the DI digital input module is mainly used for sensors, cylinder magnetic switches, access control sensors, various alarm signal

inputs, etc.; the DO digital output module is mainly used for cylinders, lasers, robots, etc.

AI analog input modules are mainly used for pressure sensors, anemometers, intake total air pressure detection, etc., and AO analog output

modules are mainly used for proportional valves.

The main reasons why this customer chose our EX series remote IO module are as follows: small size, fast communication response, good

stability of field signal transmission, strong scalability, and stable use of high-speed counter module.

03 Network topology diagram

04 Decowell EX series remote I/O

Product features:

1. Stable communication, fast response, convenient operation, and high efficiency;

2. Rich bus protocols, supporting multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link, Ethernet/IP,

Modbus-RTU, CC-Link IEF Basic, etc.;

3. Rich signal types, which can meet factory automation and process automation control. Supports digital quantity, analog quantity,

temperature module, encoder module, and free communication module;

4. Compact structure, small module size, a single I/O module supports up to 32 digital signal points;

5. Strong expansion capability, a single adapter can expand up to 32 I/O modules, and the coupler scans quickly;

6. Easy to use, standard DIN35 rail installation, plug-in terminals, tool-free installation.