Semiconductor industry

Decowell remote I/O modules are used in wafer handling equipment in the semiconductor industry

Application Background

The wafer manufacturing industry is the most automated industry among all industrial manufacturing industries. The main reason is that the

wafer manufacturing process requires high precision, high cleanliness, and high reliability, and manual participation cannot meet these

requirements.

Wafer handling is an important process in the front-end process of semiconductor manufacturing equipment, especially requiring high-precision

and high speed.

In the application of wafer handling equipment, the Decowell IO module meets the key requirements of the site such as stability, precision, and

speed, and has won the recognition of customers!

01 Industry Analysis

As a key component in the semiconductor industry, wafers need to be quickly and accurately transferred between various processing stations

in the semiconductor processing process.

Modern science and technology can produce wafers with nanometer thickness. Such expensive, precise, and fragile wafers are easily damaged

during the transmission process if they rely on manual operation, and the surface of the wafer will be contaminated during the process.

Therefore, wafer handling equipment has become one of the core equipment of wafer manufacturing. The quality of its performance directly

affects the production efficiency and manufacturing quality of the wafer, reflecting the degree of automation and reliability of the entire

processing system.

02 Process Description

Wafer handling equipment refers to the automatic handling of wafers from the wafer box or container of process A to the wafer box or container

of process B by machines. In this process, the wafers in the wafer storage box or container are handled and processed at high speed and cleanly.

In order to prevent contamination during the handling process, silicon wafers are usually placed in the handling container and assisted by robots

to achieve a series of actions from loading → processing → unloading to the wafer box.

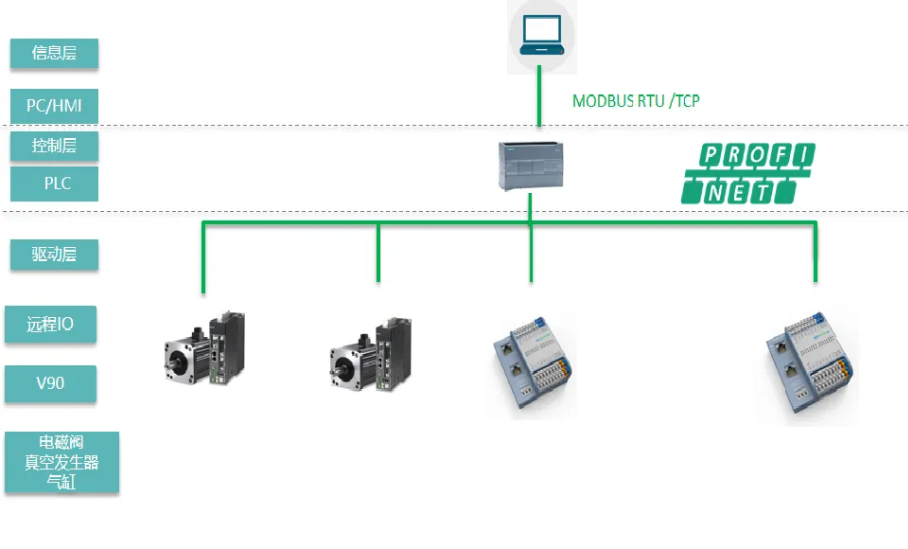

03 Decowell Solution

In this project, Decowell IO modules cooperate with photolithography machines to transfer board-level or wafer-level products. They are mainly

installed in each station of the transfer machine in a single machine-distributed manner to transmit the in-position signal and drive the

corresponding station solenoid valve. A single line mainly uses about 7 FS integrated remote IOs of our company.

Among them, the input and output points of the Decowell FS series digital modules can fully complete the conveyor line tasks and improve the

communication stability of the project.

Master station: Siemens 1200 series;

Applicable process section: Wafer handling equipment;

Project I/O configuration: Decowell FS series module digital quantity 200 points;

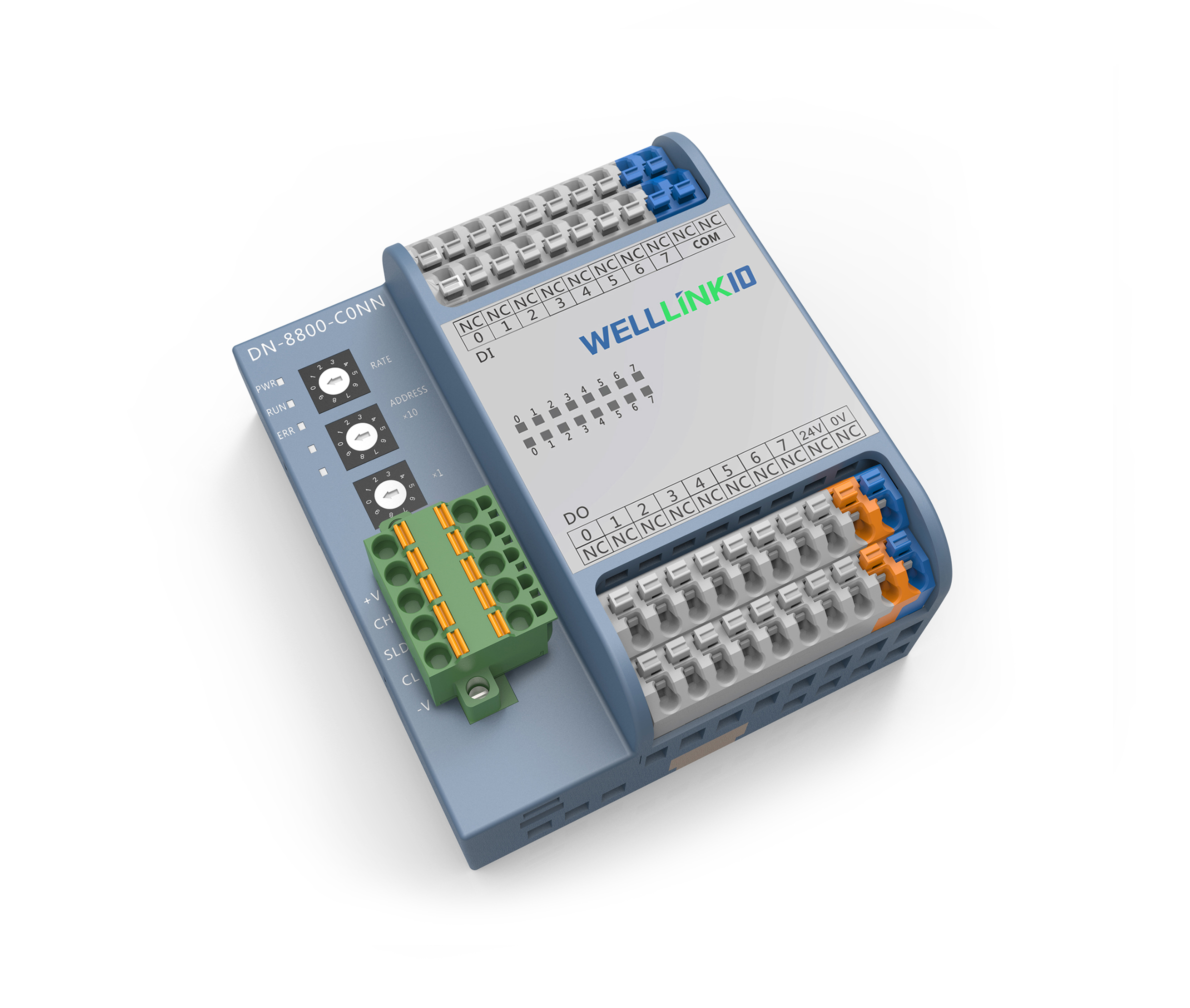

04 FS series integrated I/O

Product features:

1. Rich bus protocols, supporting mainstream industrial bus protocols EtherCAT, PROFINET, DeviceNet, CC-Link, CC-LinkIE Filed Basic, etc.;

2. Direct plug-in terminals, fast installation;

3. Small product size and compact structure;

4. Stable communication and no data packet loss;

5. Widely used in logistics industry, semiconductor industry, automated stand-alone equipment and robot workstations, etc.;