Semiconductor industry

Decowell remote I/O module is used in IC die bonding machine in semiconductor industry

Application Background

The most academic explanation of semiconductors refers to materials with conductivity between conductors and insulators at room temperature

and controllable conductivity. The semiconductors mentioned in our daily lives refer to the application of semiconductors in integrated

circuits, consumer electronics, communication systems, photovoltaic power generation, lighting applications, high-power power conversion, and

other fields.

The most well-known of these fields is integrated circuit chips, such as computer processors, mobile phone memory, flash memory, etc., so we

often refer to the semiconductor industry as the integrated circuit chip industry.

It can be said that chips are the basis for meeting all technological life. From TVs and computers to cars and mobile phones, as long as the

equipment involves human-computer interaction, chips are needed, and the manufacturing process of chips is naturally inseparable from the

the main industry of semiconductors.

01 IC Bonding Machine

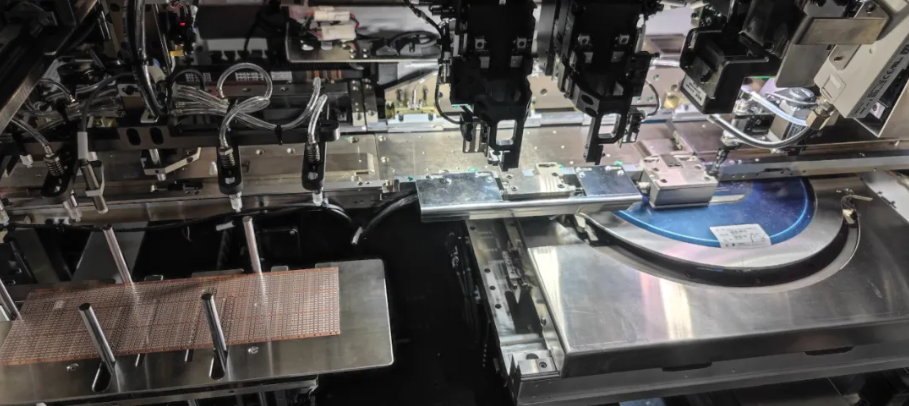

IC Bonding Machine equipment is also called crystal loading machine, chip pasting machine, and chip binding machine. It is a machine for

fixing crystals and semiconductor packaging.

It is mainly used for the lead cabinet press plate of various (WIREBONDER) gold wire ultrasonic welding equipment, as well as various

suction nozzles, ejectors, dispensing heads, porcelain nozzles, through needles, motors, carbon brushes, encoders, transmission belts

of various (DIEBONDER) chip mounting equipment, various spare parts, instruments, meters, etc. of automation equipment.

1 Definition and composition

The crystal bonder is one of the key pieces of equipment in the packaging process of LEDs, chip semiconductors, and camera mounting. The

equipment

is a typical high-speed, high-precision, fully automated equipment with a visual system on the market. The crystal bonder mainly comprises a

material picking mechanism, a material pushing mechanism, a dispensing mechanism, a dispensing platform, a swing arm mechanism, a crystal

bonding platform, a crystal finding platform, a fixture, and a material discharging mechanism.

2 Crystal bonding system operation steps

Includes the following steps:

①Image recognition, positioning, and image processing of LED chips and LED bracket boards.

②Dispense glue at a given position of the LED bracket board through a silver glue pickup device.

③ Use the chip suction device to accurately place the LED chip at the dispensing point. The operating system principle of this equipment

includes high-speed precision positioning control, visual positioning control, pneumatic suction control, and other related technologies of

optomechanical integrated systems.

3 Specific classification

Packaging and mounting machines are divided into FC packaging and mounting machines, FO packaging and mounting machines,

and 2.5D/3D mounting machines.

According to the application type, it can be divided into IC die bonding machines, discrete device die bonding machines, LED die

bonding machines (die bonding machines and COB die bonding machines), which are mainly used in semiconductor electric chips,

optical chips, optical modules, silicon optical devices, sensors, and other packaging processes.

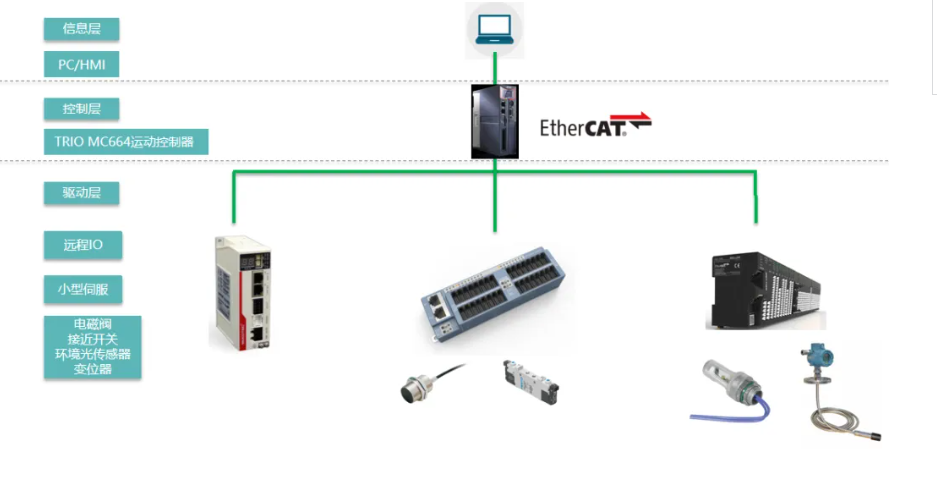

02 Decowell module application

Master station: PLC (EtherCAT protocol)

Applicable process section: IC packaging detection

Project I/O configuration: EX series I/O

Project overview: Our FS and EX series remote I/O are used in the die bonding machine. The digital input signal is mainly used for the in-place

signal of each point on the material tray, and the output signal corresponds to the solenoid valve and the gripper. The analog module is mainly

used for the motor drive of the material tray.

Application advantages: Provide customers with standardized solutions. A single station can use various models of I/O of the same series to

improve the overall efficiency of the project.

03 Network topology

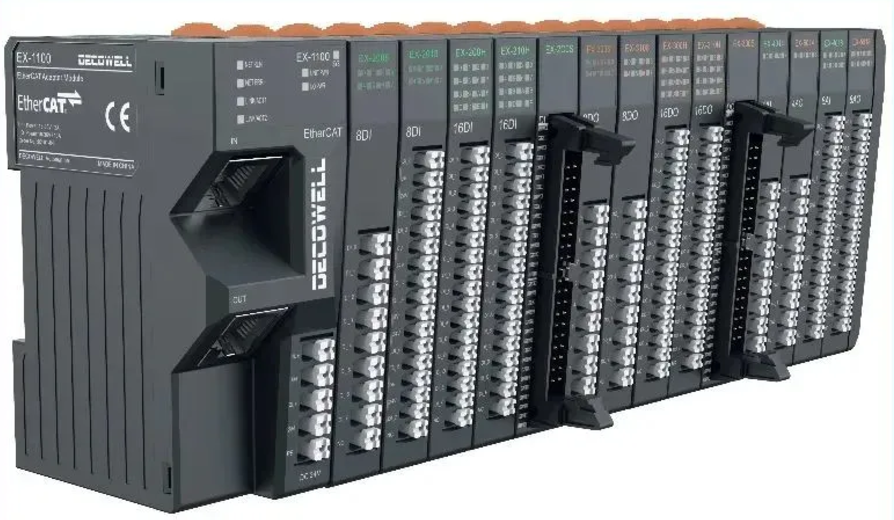

04 Decowell remote I/O

EX series card I/O

Product features:

1. Stable communication, fast response, convenient operation, and high efficiency;

2. Rich bus protocols, supporting multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link,

Ethernet/IP, Modbus-RTU, CC-Link IE Field Basic, etc.;

3. Rich signal types, which can meet factory automation and process automation control. Support digital quantity, analog quantity, temperature module, encoder module, and free communication module;

4. Compact structure, small module size, a single I/O module supports up to 32 digital signal points;

5. Strong expansion capability, a single adapter can expand up to 32 I/O modules, and the coupler scans quickly;

6. Simple and easy to use, standard DIN35 rail installation, plug-in terminals, and tool-free installation.