Lithium industry

Decowell assists lithium battery coating process, saving energy and increasing efficiency!

Background of the lithium battery industry

Lithium battery is a kind of battery with lithium metal or lithium alloy as negative electrode material and a non-aqueous electrolyte solution.

Lithium battery is mainly used in digital products in traditional fields, and in power batteries and energy storage in emerging fields.

In recent years, the output of lithium batteries in my country has increased year by year! In terms of demand, benefiting from the development

of new energy vehicles and the increase in demand for power batteries, the shipment of lithium batteries in my country has increased year by

year and the scale of the industry has exceeded 25 billion USD.

At present, the demand in the field of consumer lithium batteries is relatively saturated. In the future, with the development of global new energy

industry, electric vehicles will gradually become a large demand industry for lithium batteries, so power lithium batteries will become a

concentrated area of demand growth in the lithium battery industry.

Since 1990, China's lithium battery industry has evolved from initial imitation and reference to gradual independent innovation, from initially

only being able to provide consumer batteries to later becoming the main supplier of power batteries. China's role in the lithium battery

industry has become increasingly important.

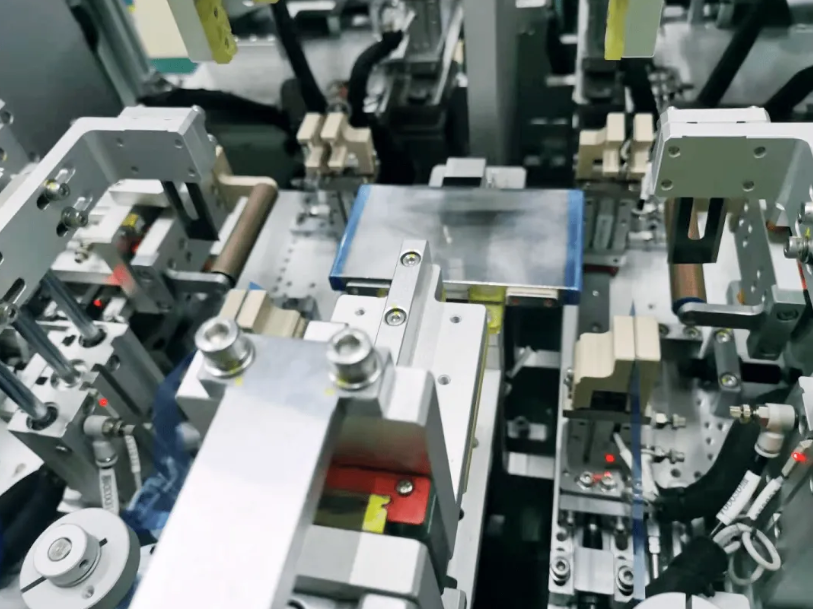

01 Lithium battery coating process

Lithium battery coating is achieved by dividing the outer surface of the battery into coating areas, pressurizing the insulating film of the

overlapping part of the insulating film in the first coating area of the battery, reducing the height difference of the overlapping part of the

insulating film, and then activating the surface energy of the insulating film in the first coating area.

Glue is applied to the insulating film in the first coating area and the glue is cured, which can protect the outer surface of the battery to a

certain extent, further improve the insulation performance of the battery, meet the requirements of the insulation performance of the battery,

and improve the safety of the battery.

02 Application of Decowell remote I/O in lithium battery coating machine

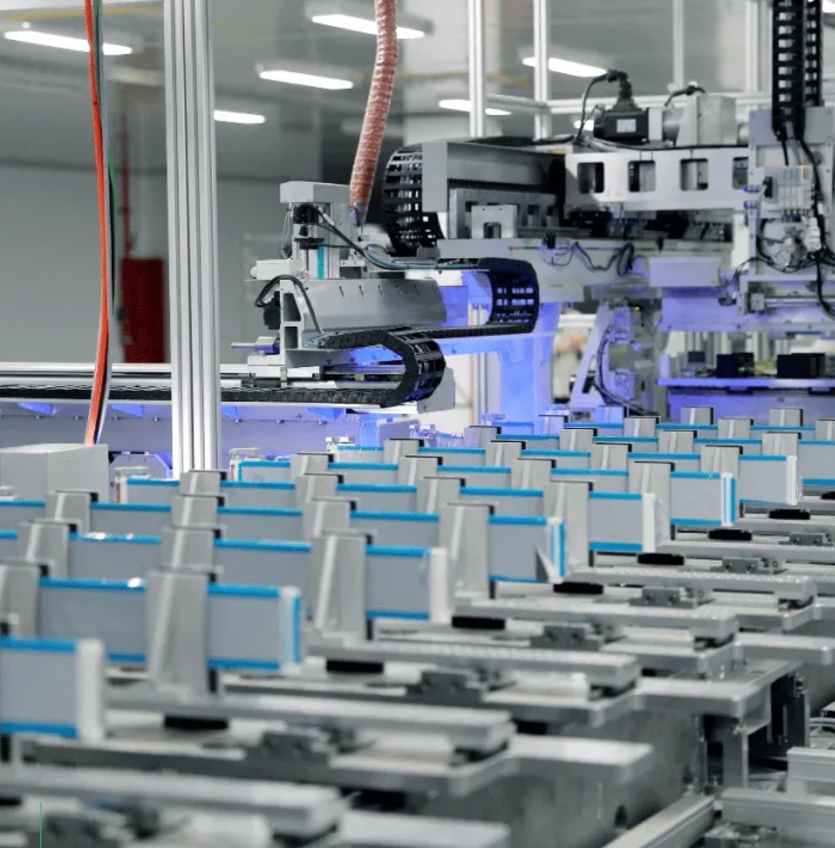

The production process of the coating machine consists of several parts such as material collection, film application, short circuit detection,

and material unloading.

The system is equipped with the Decowell EX card-type IO module to expand the number of input and output points. The input signals include:

start, stop, emergency stop, the front limit of the cell motor, the origin of the cell motor, the rear limit of the cell motor, alarm of the cell motor,

film sticking detection, short circuit detection, photoelectric switch detection of whether the cylinder is in place, and sensor detection of

whether the tape of each film sticking is attached to the cell.

Output includes: forward and reverse rotation of the cell motor, forward and reverse rotation of the unloading motor, vacuum solenoid valve for

tape sticking, short circuit detection cylinder solenoid valve, etc.

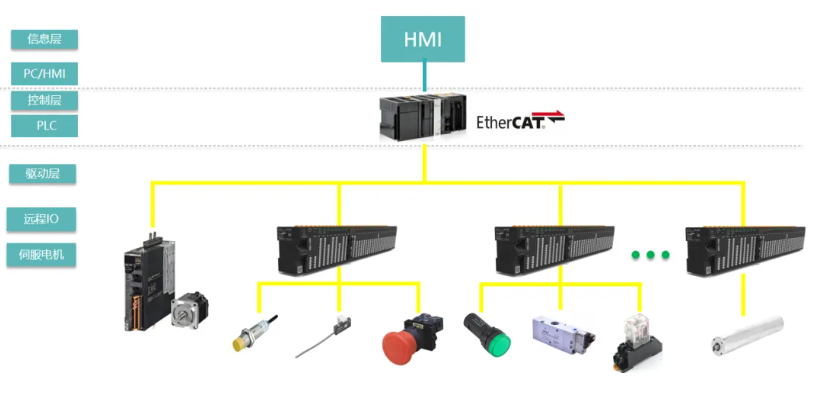

03 System topology diagram

The equipment is mainly used in the process stage of lithium battery, which also includes lithium battery insulation detection and leakage

detection and other detection process flow.

Using the Omron NJ501 controller master station, with the Decowell EX-1100 card-type remote IO, it is used to control the distribution of

production tasks in the factory. The dual-line mirror production is adopted, and the product production efficiency has been greatly improved.

04 Decowell EX series remote IO

Product features:

1. Stable communication, fast response, convenient operation, and high efficiency;

2. Rich bus protocols, supporting multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link, Ethernet/IP,

Modbus-RTU, CC-Link IEF Basic, etc.;

3. Rich signal types, which can meet factory automation and process automation control. Support digital quantity, analog quantity, temperature

module, encoder module, free communication module;

4. Compact structure, small module size, a single IO module supports up to 32 digital signal points;

5. Strong expansion capability, a single adapter can expand up to 32 IO modules, and the coupler scans quickly;

6. Simple and easy to use, standard DIN35 rail installation, plug-in terminals, and tool-free installation.