Healthcare industry

Decowell remote IO medical industry application case

01 Pharmaceutical factory environmental testing

At present, some well-known Chinese medicine factories in China have developed based on handicraft workshops in the form of front shops

and back factory and most of the remaining Chinese medicine factories were established in the 1950s.

The production of Chinese medicine factories starts with Chinese medicinal materials. According to the theory of traditional Chinese medicine

and traditional craftsmanship, they process and produce traditional Chinese patent medicines that can be taken directly, or in modern dosage

forms of injections, tablets, granules, granules, suppositories, aerosols, etc.

Since the raw materials of Chinese medicine factories are agricultural and sideline products, most of them are harvested once a year, in large

volumes, and easy to mold and deteriorate. Their products, especially honey pills and pastes, are also easy to spoil or grow insects and mites.

Therefore, Chinese medicine factories attach great importance to anti-mildew and anti-insect work in the storage of raw materials and products.

In recent years, due to the use of modern production equipment, such as closed pulverizers, high-efficiency extraction equipment, membrane

evaporators, spray dryers, and program-controlled coating machines, the production conditions and work efficiency have been greatly improved,

and the product quality and production capacity have been improved.

02 Nanjing Decowell Remote IO Application Case in the Pharmaceutical Industry

Nanjing Decowell has been deeply involved in the field of industrial control for many years and has been recognized by many customers. At

present, its products are widely used in 3C, new energy, medical, logistics, automobile, textile, packaging, steel, mining, environmental protection,

and other industries. Here are some application cases of Decowell Remote IO in the pharmaceutical industry:

Pharmaceutical Factory Production Workshop Environmental Monitoring System

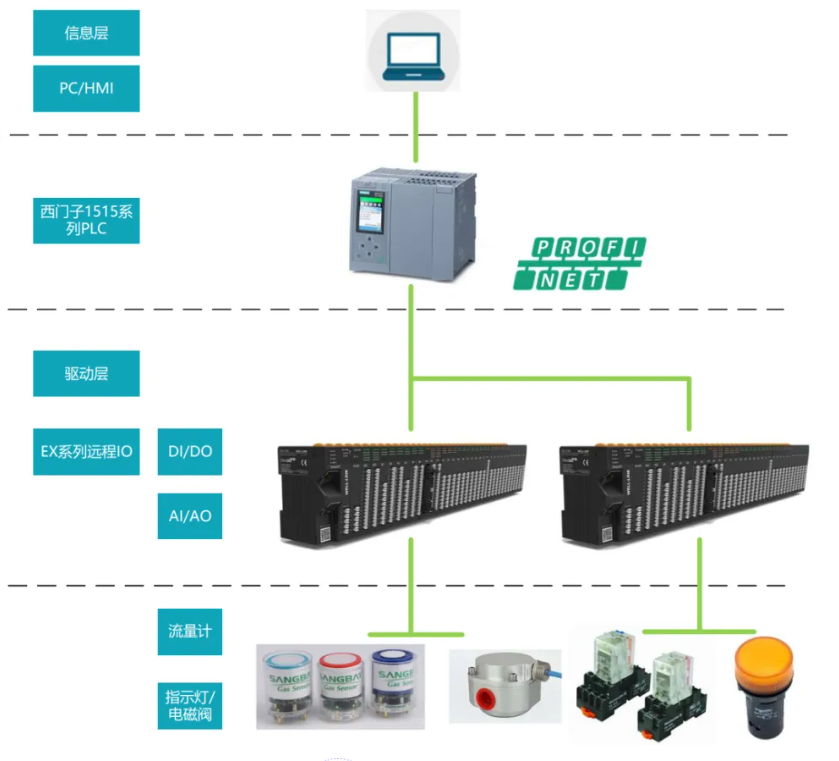

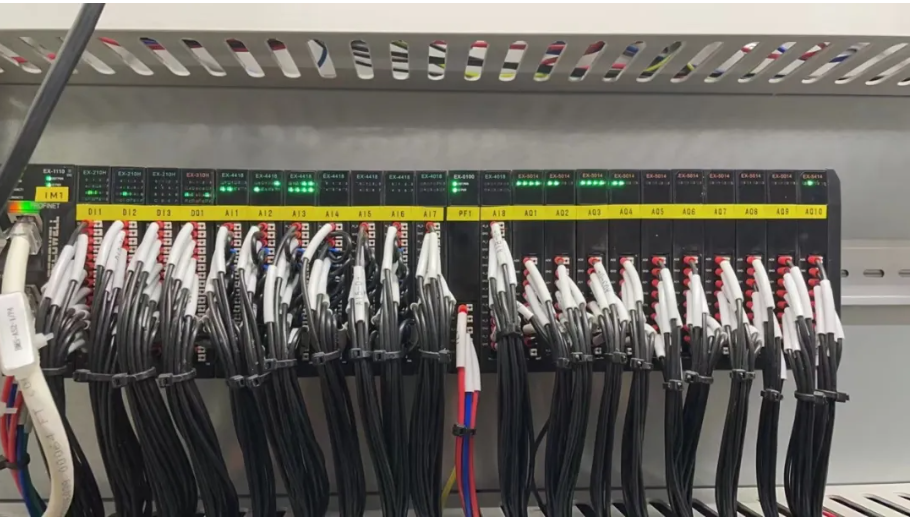

This project is applied to a large domestic pharmaceutical factory for partial automation processing and workshop environmental monitoring

system. In this project, our company's EX card-type remote IO is widely used. A single remote IO slave station can mount up to 120 analog

channels. The main station of the equipment uses Siemens 1515 series CPU and PROFINET protocol with Decowell EX series card-type modules.

Mainly through the EX card-type module to control the relay, and contactor and then control the start and stop of the three-phase asynchronous

motor. Or use digital output module to control the operation of the motor through switch quantity and inverter, to realize the conveying

work of the production line. In addition, gas and environmental detection account for the main signal point types in this project, providing

absolute stability and efficiency for pharmaceutical factories.

03 Topology diagram of environmental monitoring system in pharmaceutical production workshop

04 Equipment diagram

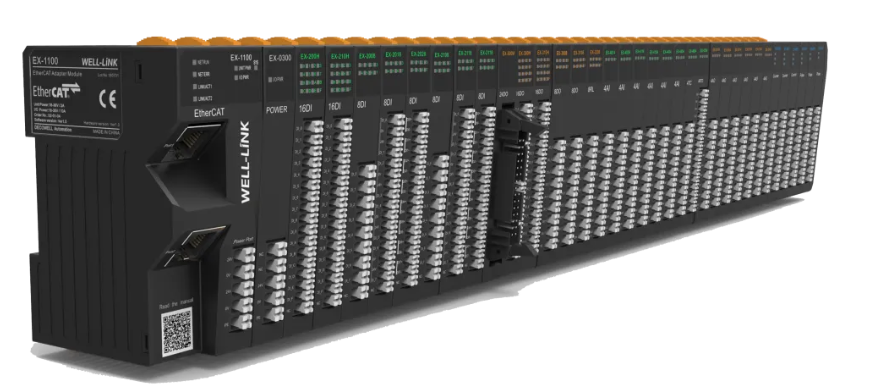

04 EX card-type module

The above case uses EX card-type remote IO. This series of products has been verified by the market for many years, with excellent quality and

stable performance.

①Strong combination, rich IO module models, one system can meet factory automation and process automation control;

②Compact structure, small size of a single module, the module can support up to 32 digital signal points;

③Rich protocols support multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link, Modbus RTU, etc.;

④Excellent performance, electrical isolation, stable communication, no data packet loss, the adapter can carry up to 32 IO modules;

⑤Output NPN/PNP/relay optional;

⑥The number of input and output channels is optional, and 8DI&8DO, 16DI&16DO, and 32DI&32DO have been launched.

For workstations with many scattered stations and a small number of single workstations, this solution can be applied.

EX series card-type module