home appliance industry

Decowell Remote I/O Module in Home Appliance Industry

01 Household appliances

Household appliances have been around for nearly a hundred years. They have freed people from heavy, trivial, and time-consuming housework,

created a more comfortable and beautiful living and working environment that is more conducive to physical and mental health, and provided a

variety of cultural and entertainment conditions. They have become a necessity for modern family life.

The production and manufacturing of household appliances will inevitably move towards automation and intelligence. More and more household

appliance companies are improving their equipment level through technological transformation and improving production efficiency by

increasing the degree of automation.

02 Nanjing Decowell Remote IO Household Appliance Industry Application Case

Nanjing Decowell has been deeply involved in the industrial control field for many years and has been recognized by many customers. At present,

its products are widely used in 3C, new energy, medical, logistics, automobile, textile, packaging, steel, mining, environmental protection, and

other industries.

Here are some examples of Decowell remote IO applications in the home appliance industry:

2.1 Air conditioning production line

Mainly used in air conditioning production lines, from loading, assembly, testing, unloading, and the entire conveyor line

Currently mainly supplied to Gree, Midea, Haier, and other well-known manufacturers

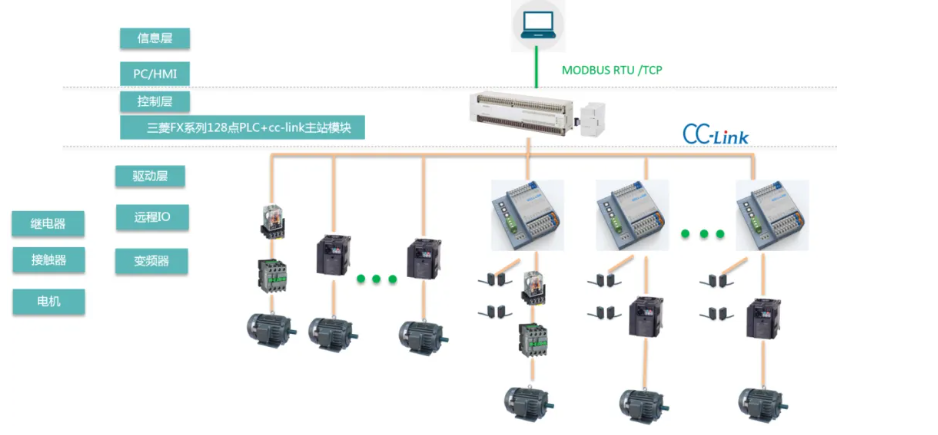

2.2 Topology diagram of air conditioning production conveyor system

The main station of this equipment uses FX3U-128M+FX-16CCL-M and CC-Link protocol with the Decowell FS series integrated module.

Mainly through the FS integrated module to control the relay and contactor to control the start and stop of the three-phase asynchronous motor.

The FS module is used to control the operation of the motor through the inverter through the switch quantity. Thus, the conveying work of the

the production line is realized.

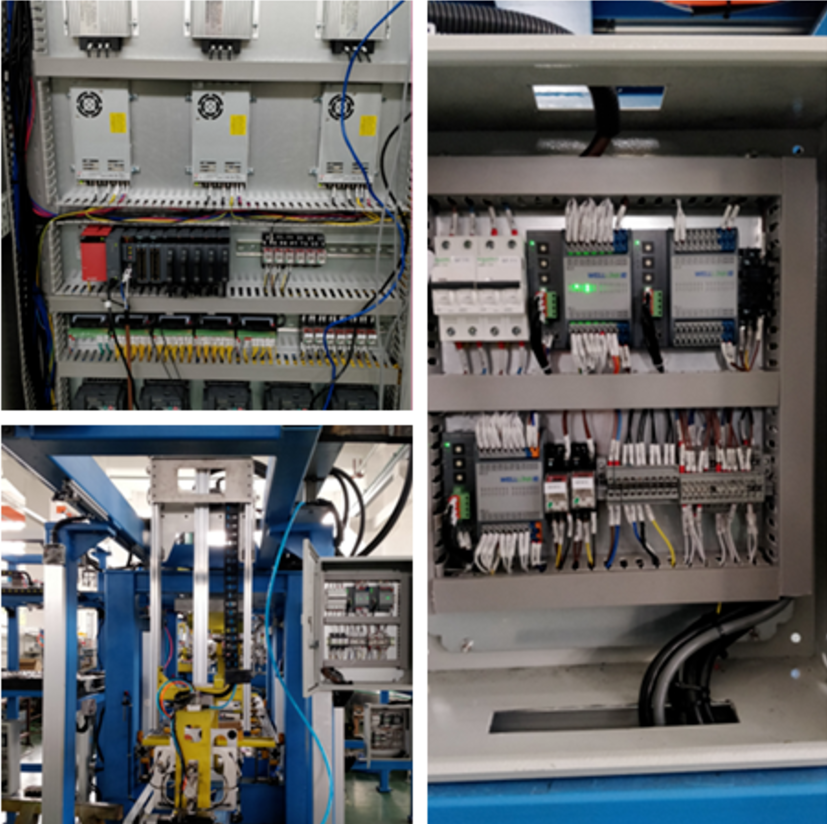

2.3 Equipment diagram

03 Home appliance shell liner production equipment

Mainly used in the production of home appliance shells, such as the production of washing machine shell liners, from incoming materials,

pressing, perforation, bending, and other process links. This equipment is mainly supplied to Vatti, Galanz, Haier, etc.

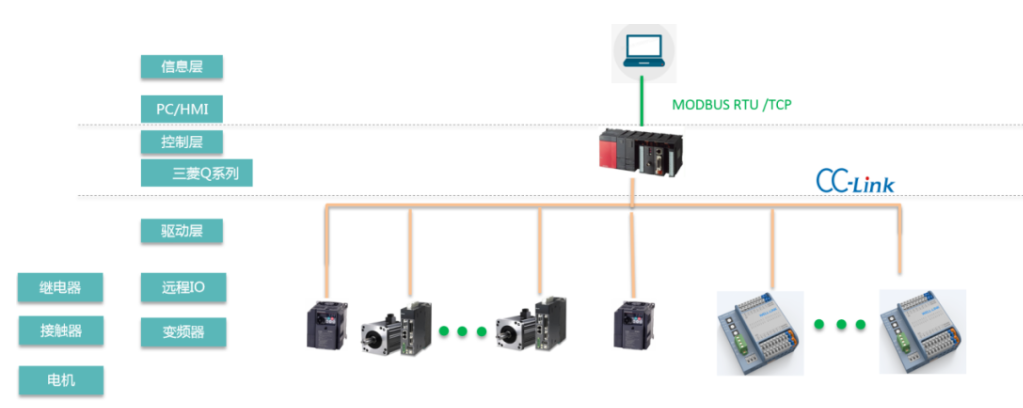

04 System topology diagram

The equipment adopts cabinet control, and different process sections use one cabinet. Each cabinet has two to three FS integrated modules.

The whole line uses about 30 modules. Mainly 32-point input modules 16-point input and 16-point output modules.

05 Equipment diagram

06 FS integrated module

Both cases above use FS integrated remote IO. FS integrated IO was released in 2017 and has been verified by the market for many years. It has

excellent quality and stable performance.

Input supports two signal types: NPN and PNP

Output supports two signal types: NPN/PNP/relay optional

The number of input and output channels is optional, and 8DI8DO, 16DI16DO, and 32DI32DO have been launched.

The bus protocols are rich, and currently supported protocols include PROFINET, EtherCAT, CC-Link, DeviceNet, CC-Link IEF Basic, and other bus

protocols.