Photovoltaic industry

Application of Decowell Remote I /O Module in Velvet Cleaning and Unloading Equipment

Nanjing Decowell has been deeply involved in industrial control for many years, and its strong research and development capabilities have created products with

reliable performance, which have been recognized by many customers. Currently, the products are widely used in industries such as 3C, new energy, medical,

logistics, automotive, textile, packaging, steel, mining, and environmental protection.

Below is an application case of Decowell Remote IO in velvet cleaning loading and unloading equipment:

1.1 Photovoltaic velvet cleaning loading and unloading machine

The velvet cleaning loading and unloading machine is a device that automatically places silicon wafers from the wafer placement box onto the velvet cleaning

machine. Generally, the function of the silicon wafer loading and unloading machine is to transfer 50-100pcs of silicon wafers from the basket to the wafer

arranging system through a belt, gradually arranging them into 5 or 8 rows, and then importing them into the main line equipment through a leather belt

lifting mechanism for use in the next process.

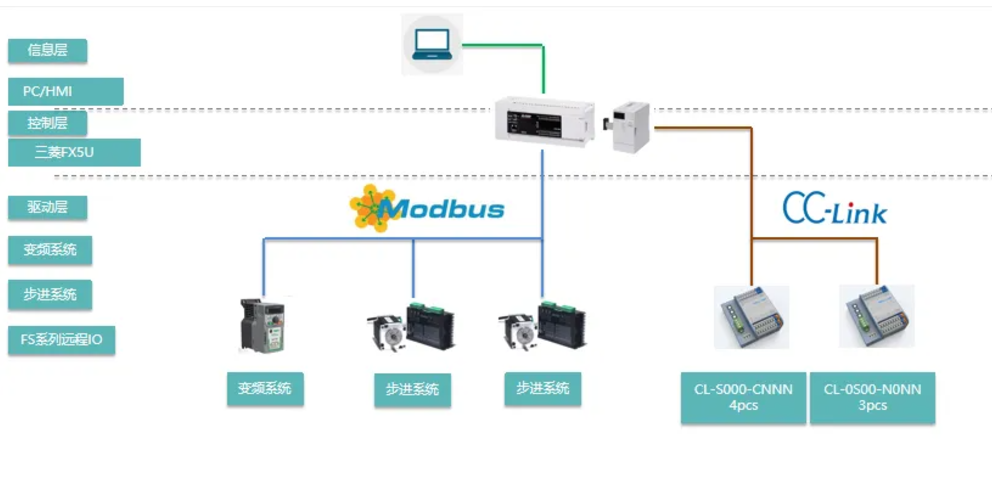

1.2 Topology diagram of velvet cleaning loading and unloading machine.

This project uses Mitsubishi FX5U series PLC, and the transmission control part adopts a Rexay stepper system and Nidec frequency converter to control various

conveyor belts inside the equipment. The PLC part adopts CC Link bus communication and Modbus communication protocol. A single velvet cleaning loading

and unloading machine uses more than 7 Decowell integrated distributed bus IO, with digital input and output points at around 250 points, mainly responsible

for sensor-in-place signal detection and driving relays and other related equipment inside the equipment.

2.3 Equipment diagram of velvet cleaning loading and unloading machine

The Decowell FS series remote IO is suitable for various occasions, with many advantages such as small size, simple wiring, stable performance, support for multiple communication protocols, optional point positions, and optional signal types. It can fully protect your equipment.