Industry News

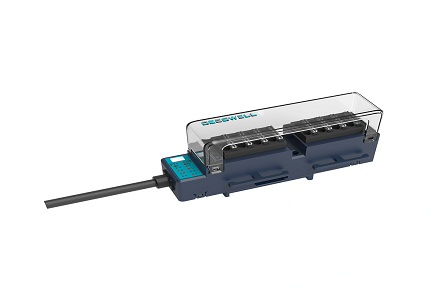

Enhancing Industrial Automation with Decowell's LS Series Digital I/O Modules

Automation is essential to enhancing productivity, efficiency, and overall system performance in the ever changing industrial world of today. Our goal at Decowell is to use our state-of-the-art LS Series Digital I/O modules to transform automation systems. For a variety of sectors, these modules are made to streamline operations, improve system dependability, and simplify wiring. The significance of Digital I/O modules, the advantages of our discrete provisioning approach, and the ways in which WellBUS technology is revolutionising problem detection and system efficiency will all be covered in this article.

What Are Digital I/O Modules and Their Importance in Automation?

Digital I/O modules are the backbone of modern industrial automation systems. These modules are responsible for controlling and monitoring digital input and output signals from various devices within a system. In essence, they act as intermediaries, facilitating communication between the control system and field devices like sensors, actuators, and switches.

At Decowell, our Digital I/O modules are designed to deliver precise and reliable performance. Our LS Series Digital I/O modules integrate seamlessly into any industrial environment, offering robust solutions for everything from simple machinery control to complex automation processes. These modules are built to handle high-speed digital signals, ensuring that your systems run smoothly and efficiently.

The importance of Digital I/O modules in modern automation cannot be overstated. They allow industries to automate processes, reduce the need for manual interventions, and improve the accuracy and speed of operations. Whether you're involved in manufacturing, logistics, or warehousing, Decowell's Digital I/O modules help enhance operational performance by ensuring real-time communication between machines and control systems.

Discrete Provisioning: The Future of Wiring in Complex Systems

One of the most significant challenges in industrial automation is wiring complexity. Traditional systems often require extensive cabling, which can be cumbersome, prone to faults, and costly to install. However, Decowell's LS Series Digital I/O modules feature a revolutionary discrete provisioning module that drastically reduces wiring requirements.

The discrete provisioning module is designed to minimize the number of cables needed in an industrial system. Instead of relying on numerous individual wires for each connection, our LS Series uses a 2-core power line to handle both signal control and power transmission. This innovative approach significantly cuts down on the amount of wiring needed, making installation faster, more cost-effective, and much less prone to errors.

Not only does this reduce the physical space needed for cables, but it also simplifies system maintenance. In environments like logistics and warehousing, where long wire runs and complex systems are common, our Digital I/O modules help eliminate the need for excessive cabling. This results in less downtime, easier troubleshooting, and more efficient overall operations.

The Advantages of WellBUS for Simplified Wiring and Fault Diagnosis

To further enhance the efficiency of industrial automation, Decowell incorporates WellBUS technology in our LS Series Digital I/O modules. WellBUS is a sophisticated communication protocol that enables multiple devices to be connected through a single bus line, greatly simplifying the wiring system. This provincial wiring approach reduces the need for redundant cables, improving data transmission speed and minimizing the risk of interference.

One of the standout features of WellBUS technology is its ability to streamline fault diagnosis. In traditional systems, identifying and troubleshooting wiring issues can be a time-consuming and complex task. With WellBUS, however, diagnostic tools are built directly into the system, providing real-time feedback and enabling technicians to identify and resolve faults quickly. This leads to reduced downtime and faster recovery times, ensuring that your operations remain as efficient as possible.

The simplicity of WellBUS also enhances system scalability. As your operations grow, the flexibility of WellBUS allows for easy expansion without the need to reconfigure the entire system. This scalability, combined with faster fault detection and a reduced need for wiring, makes Decowell's Digital I/O modules the ideal solution for businesses looking to optimize their automation systems.

Conclusion

At Decowell, we are dedicated to advancing industrial automation with innovative solutions like our LS Series Digital I/O modules. These modules are designed to streamline wiring, enhance system performance, and simplify maintenance in a variety of industries. By incorporating cutting-edge technologies like discrete provisioning and WellBUS, we provide our customers with the tools they need to stay ahead in an increasingly competitive market.

Our Digital I/O modules are the perfect solution for businesses looking to enhance automation efficiency, reduce installation costs, and improve the reliability of their systems. Whether you're in manufacturing, logistics, or warehousing, Decowell's Digital I/O modules will help you optimize your operations and drive productivity. Choose Decowell today, and take your industrial automation to the next level.