Industry News

Why Decowell's I/O Modules are the Future of Discrete Automation Solutions

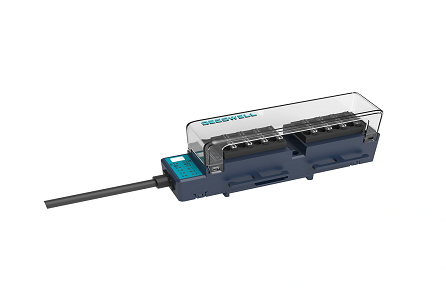

In today's fast-paced industrial landscape, businesses require reliable, efficient, and cost-effective solutions for automating operations. At Decowell, we understand the challenges faced by industries looking to streamline their processes, and that's why our input and output modules (I/O modules) are specifically designed to enhance system performance. These modules are at the forefront of industrial automation, simplifying wiring, boosting efficiency, and reducing operational costs. In this article, we'll explain how our I/O modules can transform your operations and why they're the future of discrete automation solutions.

Simplifying Complex Wiring with Decowell's I/O Modules

One of the most significant obstacles in industrial automation is the complexity of wiring. Traditional systems require extensive wiring setups that not only consume time but also lead to errors, increased labor costs, and difficulty in maintenance. At Decowell, our I/O modules provide a streamlined approach to wiring, allowing businesses to simplify and optimize their automation systems.

Our input and output modules use a unique 2-core power line technology to control signals across long industrial lines, significantly reducing the need for multiple wires. This innovative design ensures that power and signal transmission occur simultaneously over the same lines, drastically cutting down on wiring complexity. By minimizing the number of cables required, Decowell's I/O modules save valuable time during installation and reduce the space needed for wiring setups.

Moreover, the reduced wiring setup minimizes the risk of installation errors, resulting in a more efficient process. Whether in manufacturing, logistics, or warehousing, Decowell's I/O modules allow industries to streamline their operations, reduce installation times, and ultimately save resources.

Enhanced System Diagnostics for Maximum Efficiency

In any industrial environment, maintaining uptime is critical to ensure that operations run smoothly. Downtime can be costly, and detecting issues early is key to minimizing disruptions. This is where Decowell's I/O modules truly shine.

Our I/O modules come equipped with advanced diagnostic capabilities that help users quickly identify and address potential problems. Features like under-voltage, over-voltage, and broken wire detection are built into every input and output module we offer. These functions help to pinpoint issues in real-time, allowing operators to take corrective actions before they lead to costly system failures.

With these built-in diagnostic tools, Decowell's I/O modules enable faster response times and more efficient maintenance. Our modules monitor system performance and provide valuable feedback, enhancing overall system reliability. By catching issues early, businesses can significantly reduce downtime and improve the productivity of their operations, making Decowell's I/O modules an indispensable asset for maximizing operational efficiency.

Reducing Operational Costs with Power Carrier Technology

At Decowell, we continuously innovate to bring our customers cost-effective solutions. One of the key technologies that set our I/O modules apart is the power carrier technology. This groundbreaking feature optimizes power management by allowing power and signal transmission to occur over the same 2-core line. This means fewer cables are needed to manage both power and data signals, which leads to lower material costs and more straightforward system configurations.

The benefits of this innovative technology are immense. Industries such as manufacturing, warehousing, and logistics-where systems often span large areas-can see significant reductions in wiring costs. With fewer cables to maintain and replace, businesses can lower their long-term operational expenses. Additionally, the optimized power management reduces the risk of power-related failures, making systems more reliable and durable.

Power carrier technology also allows for better system scalability. As industrial automation grows, Decowell's I/O modules can easily expand without the need for complex re-wiring or new power supplies, further enhancing cost-efficiency. This scalability ensures that your automation systems are future-proof, adapting to your needs as your business evolves.

Conclusion

At Decowell, we providing innovative solutions that enhance the efficiency, reliability, and cost-effectiveness of industrial automation systems. Our input and output modules are specifically designed to simplify wiring, enhance system diagnostics, and reduce operational costs, making them an essential component of any automation setup.

With advanced technologies like power carrier and diagnostic capabilities, Decowell's I/O modules are not only making systems easier to install and maintain but also improving overall system performance. As industries continue to adopt more automated solutions, Decowell remains at the forefront, providing flexible, reliable, and cost-effective I/O modules that are ready to meet the demands of the future.

By choosing Decowell, you're choosing a partner committed to simplifying your operations and maximizing your return on investment. Let us help you streamline your automation processes today with our innovative input and output modules.