Industry News

Boosting Industrial Efficiency with Digital I/O and Discrete Control Input/Output Devices from DECOWELL

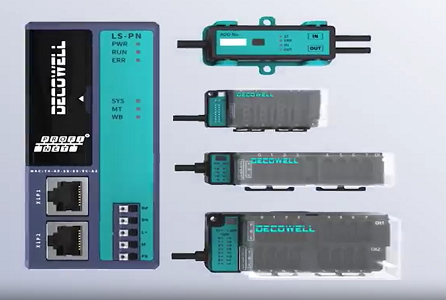

At DECOWELL, we are aware of how important discrete control input/output devices and digital I/O are to the optimization of industrial automation. Our cutting-edge solutions, which are fueled by the sophisticated WellBUS system, are made to be dependable, user-friendly, and incredibly strong, giving companies the resources they require to streamline intricate processes. Our digital I/O solutions are designed to facilitate smooth industrial automation, whether that means assuring quicker installation, better diagnostics, or increased system reliability.

The Power of WellBUS: A Revolution in Digital I/O Systems

At the heart of DECOWELL’s digital I/O solutions lies our innovative WellBUS technology. This advanced system provides unmatched flexibility and ease of use, making it a game-changer in industrial automation. WellBUS stands out for its scalability, accommodating up to 128 slave devices and offering a capacity for up to 512 inputs and 512 outputs per master station. This high level of scalability makes it an ideal choice for businesses seeking reliable systems capable of handling a wide range of industrial applications, from small-scale setups to expansive systems with complex needs.

A major advantage of WellBUS technology is its ability to cover vast distances with a communication range of up to 200 meters, ensuring smooth operation even for large systems spread over considerable distances. This feature makes our system particularly suitable for industries with sprawling production floors or widespread installations. Regardless of the scale of your automation setup, DECOWELL’s discrete control input/output devices offer seamless operation with minimal latency, enabling continuous, uninterrupted workflows.

Flexibility and Topology: Tailoring Solutions for Your Needs

Another key advantage of DECOWELL’s digital I/O systems is their exceptional flexibility in system design. The WellBUS system supports multiple topology layouts, giving you the freedom to design your system in a way that best suits your specific operational requirements. Whether you need a T-branch, star, or tree configuration, our system can adapt to a wide range of layouts, ensuring that your automation system is both effective and scalable.

This flexibility also extends to how you connect branches and modules within your automation system. DECOWELL’s digital I/O systems support various solutions that allow you to customize your system's setup based on your unique operational environment. Whether your setup demands a centralized configuration or distributed networked devices, WellBUS offers the versatility to ensure optimal performance without compromising reliability.

The adaptability of our digital I/O systems ensures that businesses can meet the demands of complex industrial applications, from assembly lines and material handling to sophisticated monitoring and control processes. You can be confident that our solutions will grow with your business and continue to deliver exceptional results as your operations expand.

Simplified Troubleshooting and Maintenance with WellBUSTesterTool

At DECOWELL, we believe that commissioning, troubleshooting, and maintaining industrial automation systems should be as simple and efficient as possible. To support this goal, we offer the WellBUSTesterTool, a powerful software suite designed to make debugging and diagnostics more intuitive than ever before. This tool is a game-changer for operators, allowing them to easily monitor the status of slave stations, manage slave addressing, and perform dot break detection with just a few clicks.

The WellBUSTesterTool enhances system diagnostics by providing real-time feedback on system performance. Operators can instantly detect issues such as cable breakage, short circuits, voltage fluctuations, and other system irregularities that could disrupt operations. The tool's user-friendly interface makes it easy to troubleshoot and resolve problems, ensuring minimal downtime and uninterrupted system performance.

Furthermore, the WellBUSTesterTool comes with alarm message prompts that notify operators of abnormal conditions or critical system issues. These alerts help to ensure a proactive approach to maintenance, reducing the likelihood of unplanned outages. By identifying and addressing potential faults early on, businesses can avoid costly disruptions and keep their automation systems running smoothly at all times.

Conclusion

DECOWELL’s digital I/O solutions and the WellBUS system provide an ideal foundation for businesses looking to optimize their industrial automation systems. Our solutions are not only designed to simplify installation but also to improve system reliability, enhance diagnostic capabilities, and reduce maintenance complexity. By utilizing WellBUS technology, businesses can deploy automation systems with greater ease, improve productivity, and reduce downtime.

With WellBUS, companies benefit from a scalable, flexible, and highly reliable system that adapts to their changing needs. The comprehensive diagnostic tools and flexible topology options ensure that operations continue to run smoothly, no matter how complex or expansive the automation setup becomes. By partnering with DECOWELL, you’re investing in a future-ready solution that will continue to meet your automation needs as your business evolves.