Lithium industry

Decowell remote IO module is applied to the lithium battery PACK line in the new energy industry

01 Industry Analysis

The energy storage battery PACK process combines multiple single cells to form a complete battery pack. Usually, the energy storage battery PACK process

is completed on an automated production line, which includes steps such as battery cell detection, sorting, grouping, and assembly. Each step requires strict

control and management to ensure the performance and quality of the energy storage battery PACK.

As a key step in the production, design, and application of new energy lithium-ion power battery systems, PACK is the core link connecting upstream battery

cell production and downstream vehicle application.

02Process Description

The energy storage battery assembly line is mainly divided into pole piece production, battery cell production, and detection and assembly.

1. Pole piece production

The process of making battery cathode pole pieces and anode pole pieces mainly includes stirring, coating, and die cutting.

Stirring is to mix the battery raw materials into slurry, the coating is to apply the slurry to the anode foil and cathode foil, and die cutting is the process of

cutting the foil into welding pole ears. Finally, the rolled pole piece rolls will be transported to the next process.

2. Cell production

The two pole pieces are rolled into a single-pack battery block. The main processes include winding, welding, shelling, and liquid injection. Winding is to roll

the two pole pieces into a single battery core, and welding is to weld the battery core to the battery electrode sheet. Shelling is to install the processed battery

core on a fixed outer shell. Liquid injection is to fill the electrolyte into the battery shell.

3. Testing and assembly

The final process is mainly formation, capacity detection, and PACK. The formation will put the battery into a special container and let it stand. Capacity detection

will test the performance and safety of the battery. The final PACK will package a single qualified battery into a battery pack.

03Pain points on site

The lithium battery PACK production line integrates many types of automation equipment such as in-place detection photoelectric switches, proximity switches,

pneumatic solenoid valves, welding robots, etc. How to quickly, accurately, and conveniently collect and control these signals and equipment has become a key

link in the automation of the entire line.

An efficient automated PACK production line also requires the configuration of I/O modules. Dekewell Automation I/O modules are widely used in welding robot

fixtures, conveying lifting platforms, rotary tables, and other workstations to collect sensor in-place signals and output cylinder action instructions.

04Decowell Solution

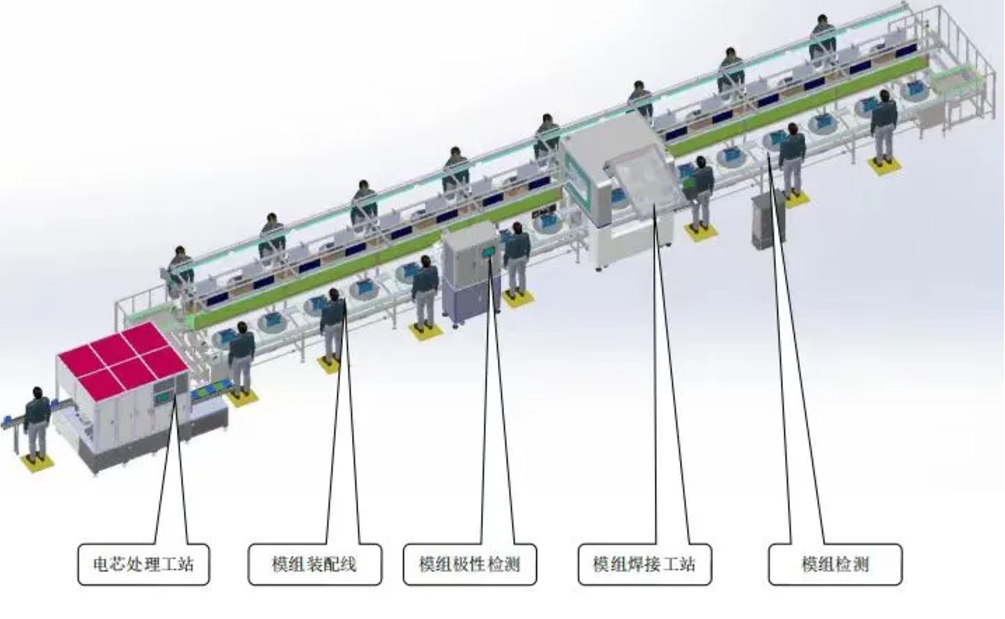

The lithium battery PACK line is used after liquid injection. The following figure is the application scenario of the I/O module of the lithium battery PACK production

line of a leading domestic new energy enterprise.

The single transmission system of this project is divided into five areas, with a high degree of automation and many on-site signal points. The transmission system

is mainly built by electric rollers, and a FANUC six-axis robot is used at the end for material handling and stacking.

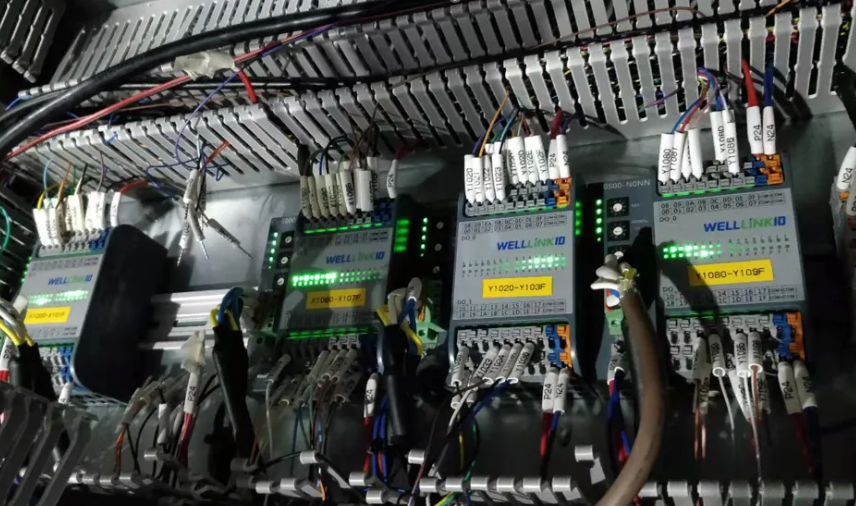

The automation system uses Omron series PLC, and the network communication uses DeviceNet protocol. It uses about 300 FS remote I/O modules of our company, which

are responsible for the signal collection of the robot gripper of the line body in-place signal, and connect on-site sensors, solenoid valves, and other equipment.

The application of Decowell I/O modules replaces Omron's local solution, reducing customer costs and improving the stability of on-site signal transmission. Help

customers improve the performance of automated production lines in all aspects, achieve efficient data collection and transmission, ensure safe communication,

and control costs.

Master station: Omron CJ series

Applicable process section: lithium battery pack packaging, transmission system

Project I/O configuration: DN-HH00-C0NN*300 digital quantity 4500 points

05FS series integrated I/O

Product features:

1. Multiple bus protocols, supporting mainstream industrial bus protocols EtherCAT, PROFINET, DeviceNet, CC-Link, CC-LinkIE Filed Basic, etc.;

2. Direct plug-in terminals, fast installation;

3. Small product size and compact structure;

4. Stable communication and no data packet loss;

5. Widely used, including logistics industry, education industry, automated stand-alone equipment and robot workstations, etc.;