Photovoltaic industry

Application case of Decokwell remote I/O module applied to the photovoltaic industry alkaline washing velvet machine.

Solar photovoltaic power generation, as an emerging renewable energy source, effectively alleviates

the energy shortage problem. The widespread application of electrical automation technology has

greatly improved the production efficiency of solar cells.

The Decowell FS series integrated IO has solved pain points such as high wiring costs in the production

of solar cells, and has received high recognition from customers!

01. Industry Analysis

Wet process refers to the manufacturing process that requires the use of chemical solutions, and

is widely used in the manufacturing processes of integrated circuits, flat panel displays, solar photovoltaics,

and other fields.

In the production process of solar cells, the wet process is the first step. The raw cells obtained from the

higher-level manufacturer or raw material factory will start a new life here. At the beginning of the life of

the cells, wet processes such as velvet making are also one of the most difficult processes to control in the

entire production process.

02. Process Description

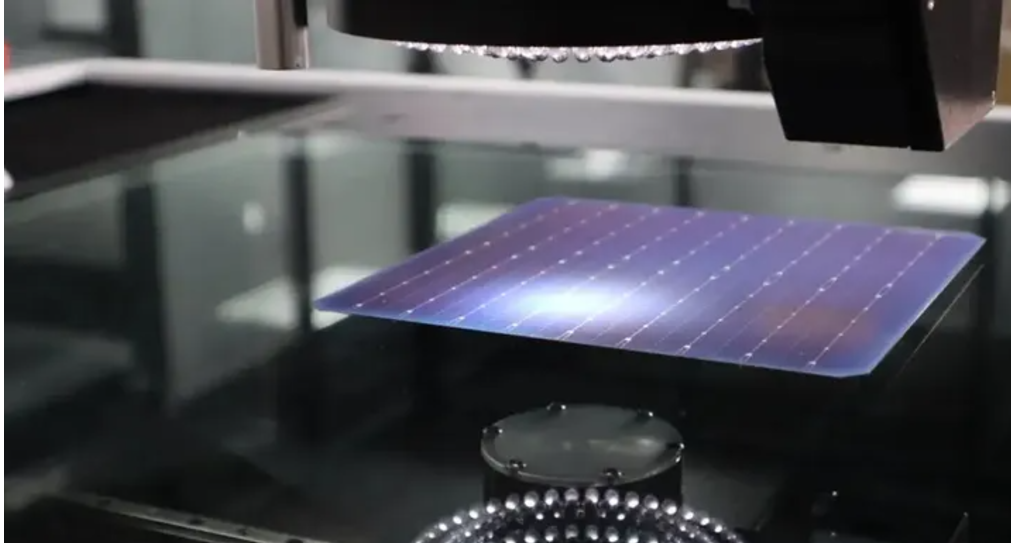

Velvet-making for photovoltaic cells is a process of treating the surface of photovoltaic cells, which can

improve the photoelectric conversion efficiency of the cells. The main principle of producing velvet for

photovoltaic cells is to form a layer of fine texture structure on the surface of the cells, thereby increasing

the scattering and absorption of light and improving the photoelectric conversion efficiency.

Velvet can make light reflect multiple times on the surface of the battery cell, increasing the interaction

between light and the battery cell, thereby enhancing the absorption capacity of the battery cell for light.

The following is the velvet production process:

03. Pain points on site

1. The length of the velvet-making machine equipment is relatively long.

If traditional local IO is used, it will greatly increase the wiring cost, and the construction difficulty will be

high. It is not easy to troubleshoot when faults occur, which will affect the production schedule.

2. The photovoltaic velvet machine has multiple input and output points:

Sensor in place signal, temperature measurement signal; Output signals for driving relays, solenoid

valves, and other related equipment. If traditional PLC expansion modules are used, it greatly increases

module costs and occupies a large amount of cabinet space during installation, making wiring difficult.

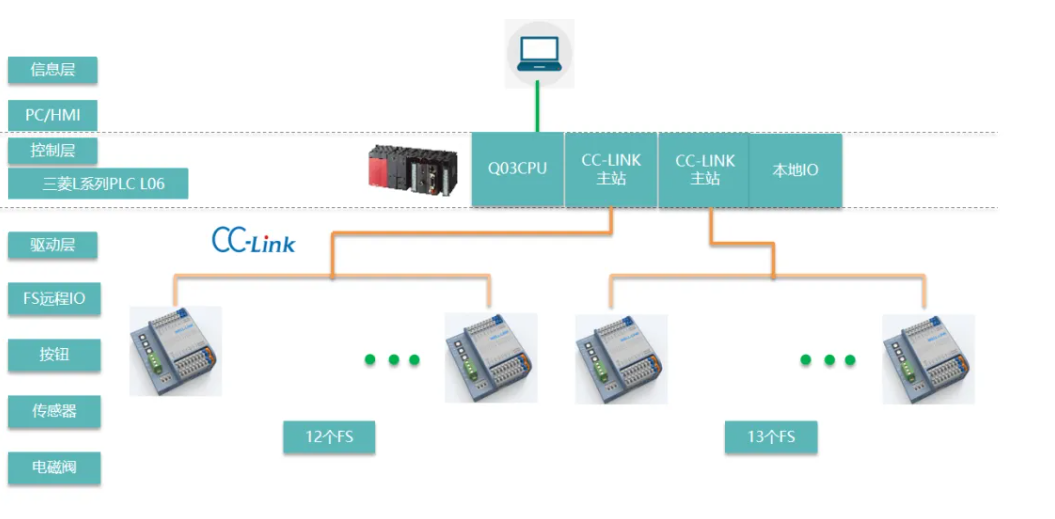

04. Decowell Automation Solutions

The Decowell FS series integrated IO replaces the original local IO solution on the customer's site,

saving a lot of wiring work. At the same time, the FS module is easy to install, and faults on site are

easy to troubleshoot and solve, ensuring stability and production efficiency in the production process,

and helping customers reduce costs and increase efficiency!

This project is mainly located in a well-known photovoltaic production base in China, with over 30 FS remote IO modules

per machine. The front end mainly interfaces with loading and positioning detection for collaborative processing of

photovoltaic panel loading and unloading work, while the back end interacts with servo motors and robots for signal

interaction to guide batch unloading actions.