Chemical industry

Decowell helps the chemical industry move towards green, safe, and sustainable development!

Chemical Industry Background

The chemical industry is an important industry related to the national economic lifeline and strategic security.

Since 2010, my country's chemical output has become the world's first, and in 2018, chemical output accounted for 40% of the world's.

The production process of the chemical industry is complex, there are many pollution-producing links, the composition of pollutants is complex,

and the treatment is difficult. Environmental safety accidents also occur from time to time, especially the total amount of industrial "three wastes"

emissions are large.

The industry characteristics of high output value and heavy pollution require the chemical industry to actively explore green, low-carbon, safe,

and environmentally friendly clean production processes and pollution prevention and control technologies. "Green chemistry" has become the

mainstream trend of the future development of the chemical industry.

01 The main process of the chemical wastewater monitoring process

When monitoring the overall treatment efficiency of sewage treatment facilities, monitoring points are set at the water inlet of each sewage

entering the sewage treatment facility and the water outlet of the sewage treatment facility.

When monitoring the treatment efficiency of each sewage treatment unit, monitoring points are set at the water inlet of each sewage entering

the sewage treatment unit and the water outlet of the sewage treatment unit.

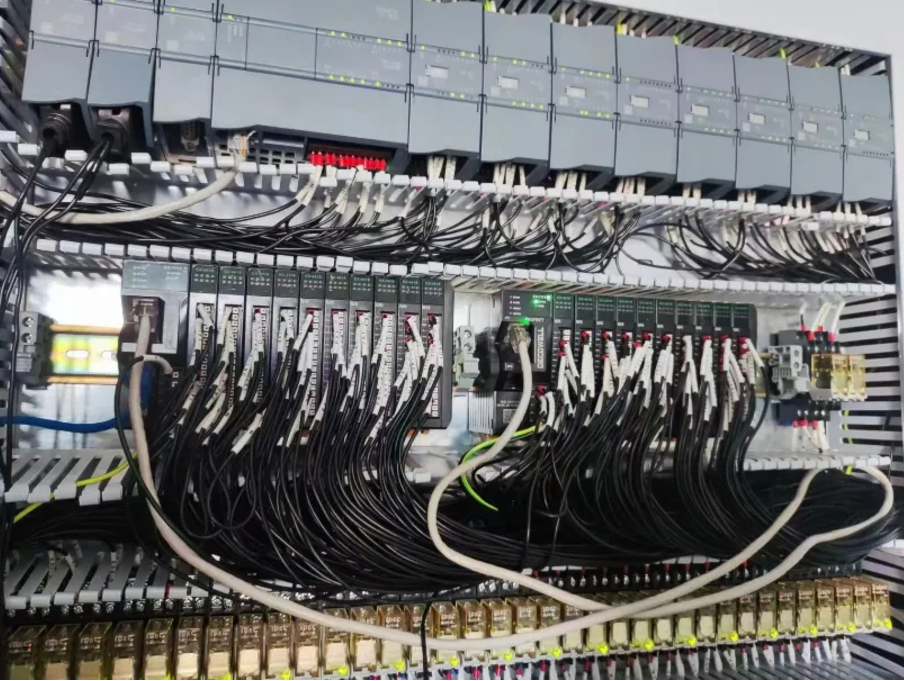

02 Decowell Remote I/O

Application in Chemical Wastewater Treatment

The system is equipped with The Decowell EX card-type I/O module, which expands analog input signals and is used to monitor the sewage flow

in the enterprise within a certain period.

Each chemical enterprise has its own management pipeline, each pipeline corresponds to a detection cabinet, and the cabinet has a

corresponding sampling detection system and flow meter, a single flow meter corresponds to a remote I/O module, and then the remote I/O

module is used to collect and send to the PLC.

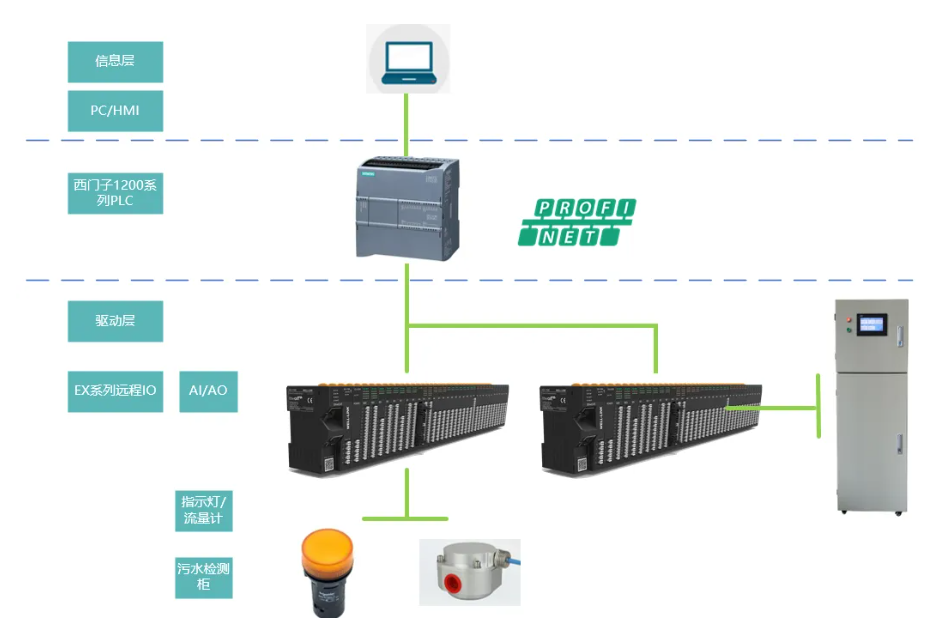

03 System topology diagram

This equipment is mainly used in the chemical wastewater detection process stage. Using Siemens 1200 controller master station, with

Decowell EX-1110 card-type remote I/O is used to detect the amount of sewage discharged by each chemical enterprise every day.

The sewage treatment monitoring system can effectively assist the sewage treatment of water plants, improve the efficiency of sewage

treatment, reduce the operating costs of water plants and protect the ecological environment.

04 Decowell EX series remote I/O

Product features:

1. Stable communication, fast response, convenient operation, and high efficiency;

2. Rich bus protocols, supporting multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link, Ethernet/IP,

Modbus-RTU, CC-Link IEF Basic, etc.;

3. Rich signal types, which can meet factory automation and process automation control. Support digital quantity, analog quantity,

temperature module, encoder module, free communication module;

4. Compact structure, small module size, a single I/O module supports up to 32 digital signal points;

5. Strong expansion capability, a single adapter can expand up to 32 I/O modules, and the coupler scans quickly;

6. Simple and easy to use, standard DIN35 rail installation, plug-in terminals, and tool-free installation.