Automotive

Application of Decowell EX Series Card I/O in Automotive Welding Production Line

Welding is called mechanical tailoring, which is responsible for welding the stamped workpieces together and is widely used in the manufacturing industry.

Welding has the same meaning as welding, and the degree of automation and flexibility of welding determines the development prospects and future of welding.

The welding workshop in automobile manufacturing includes welding tongs-welding machines-conveyor lines, etc.

01Automobile welding industry process

The car body is a structural part composed of thin plates. The stamped sheet is assembled and welded to form the body shell, also known as the body in white.

Therefore, welding is the key to body formation and the main part of the body manufacturing process.

The automobile production line is a production line for automobile assembly lines. Because its production line processes include welding, stamping, painting,

powertrain, etc., automobile manufacturers have improved the level of automation. There have been three changes in the development history of large-scale

industrial production methods of automobiles: production line mode, automobile platform production, and "modular" production mode.

02Module application

This project is applied to the automobile welding production line to weld automobile parts such as doors and seats.

In this project, the PLC used in the main station communicates with the Decowell remote IO module using the main body PROFINET communication interface.

Among them, the Digital input module is mainly used for APT buttons and fixture in-place sensors, cylinder magnetic switches, access control sensors, various

alarm signal inputs, etc.; the Digital output module is mainly used for (fixture) welding parts fixation, cylinders, lasers, etc.

The Analog input module is mainly used for pressure sensor detection, and the Analog output module is mainly used for output proportional valves.

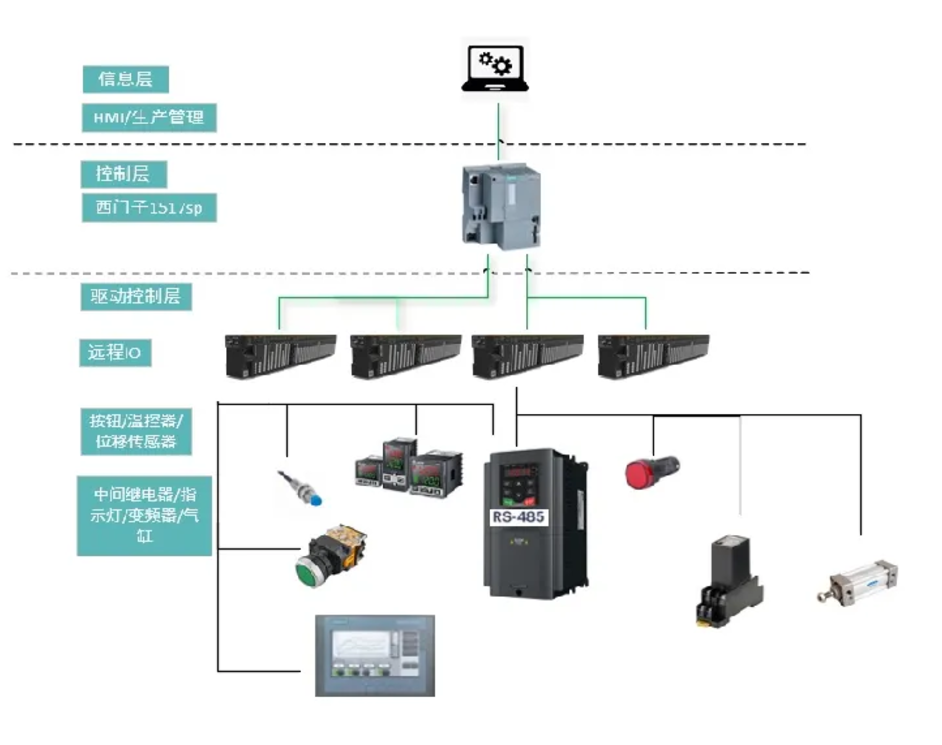

03Network topology diagram

04Decowell EX series Remote I/O

Product features:

1. Stable communication, fast response, convenient operation, and high efficiency;

2. Rich bus protocols, supporting multiple communication protocols, such as EtherCAT, PROFINET, DeviceNet, CC-Link, Ethernet/IP, Modbus-RTU, CC-Link IEF

Basic, etc.;

3. Multiple signal types, which can meet factory automation and process automation control. Supports digital quantity, analog quantity, temperature module, encoder

module, and free communication module;

4. Compact structure, small module size, a single I/O module supports up to 32 digital signal points;

5. Strong expansion capability, a single adapter can expand up to 32 I/O modules, and the coupler scans quickly;

6. Easy to use, standard DIN35 rail installation, plug-in terminals, tool-free installation.